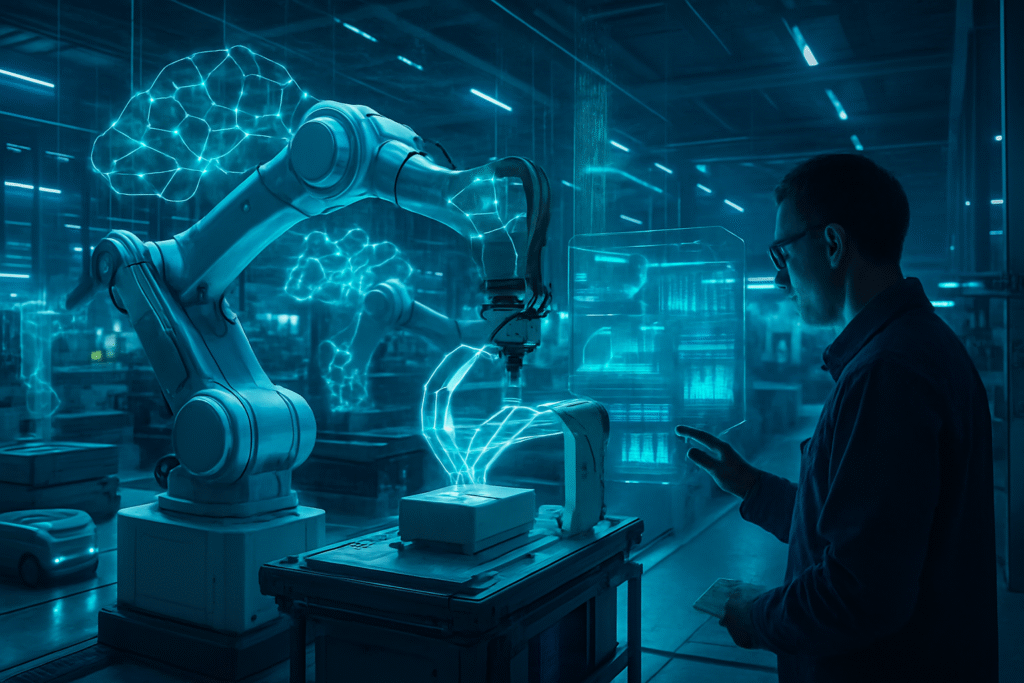

The manufacturing sector is on the cusp of a profound transformation, driven by the accelerating integration of Artificial Intelligence (AI). From optimizing complex supply chains to orchestrating robotic fleets, AI is redefining efficiency, quality, and adaptability on the factory floor. Leading this charge are innovative initiatives like Georgia AIM and the pioneering 'model factory' approach championed by tech giant Amazon (NASDAQ: AMZN), both showcasing how intelligent AI agents are not just automating, but truly optimizing business processes and production at an unprecedented scale. This shift marks a pivotal moment, promising a future where factories are not merely automated, but intelligent, self-optimizing ecosystems.

The Technical Backbone of Intelligent Manufacturing

The advancements driving this revolution are deeply rooted in sophisticated AI technologies. Georgia AIM (Artificial Intelligence in Manufacturing), a $65 million initiative supported by the U.S. Economic Development Administration (EDA), exemplifies a collaborative, statewide effort to embed AI into manufacturing. Its core involves establishing AI Manufacturing Pilot Facilities (AI-MPF) like the one at Georgia Tech, which serve as crucial testbeds for scaling AI technologies and fostering synergistic partnerships between industry, academia, and local communities. The initiative focuses on developing a skilled workforce through K-12 education, technical colleges, and university programs, alongside specialized workforce training, ensuring a sustainable talent pipeline for AI-driven manufacturing.

Amazon's 'model factory' approach, particularly evident in its vast network of fulfillment centers, offers a living laboratory for AI development. Amazon (NASDAQ: AMZN) utilizes its extensive internal systems as "reinforcement learning gyms," accelerating the refinement of its AI models and enterprise AI tools. With over one million robots deployed globally, Amazon is the world's largest operator of mobile robotics. Systems like "Sequoia," a multilevel containerized inventory system, and robotic arms such as "Robin," "Cardinal," and "Sparrow," which sort, stack, and consolidate millions of items, showcase a seamless integration of AI and robotics. A key innovation is "DeepFleet," a new generative AI foundation model powering Amazon's robotic fleet. This intelligent traffic management system coordinates robot movements across the fulfillment network, improving travel efficiency by 10% and significantly contributing to faster deliveries and reduced operational costs. These approaches differ from previous automation efforts by moving beyond rigid, pre-programmed tasks to dynamic, learning-based systems that adapt and optimize in real-time, leveraging vast datasets for continuous improvement.

Industry Implications and Competitive Landscape

The pervasive integration of AI in manufacturing carries significant implications for AI companies, tech giants, and startups alike. Tech behemoths like Amazon (NASDAQ: AMZN) stand to benefit immensely, not only from the operational efficiencies within their own vast logistics networks but also by leveraging their expertise through cloud services. Amazon Web Services (AWS) is already providing manufacturers with cloud-based AI and machine learning tools, enabling solutions for real-time operational visibility, automated quality inspection via computer vision, and predictive maintenance. This strategic move positions AWS as a critical enabler for other companies seeking to adopt intelligent manufacturing practices, thereby extending Amazon's influence beyond e-commerce into industrial AI.

For specialized AI startups, this evolving landscape presents fertile ground for innovation. Companies focusing on niche AI applications—such as advanced predictive maintenance algorithms, specialized computer vision for defect detection, or AI agents for dynamic production scheduling—can find significant market opportunities. The competitive implications are clear: manufacturers that fail to embrace AI risk being outmaneuvered by more agile, data-driven competitors. The ability to optimize production, reduce waste, and respond swiftly to market changes through AI will become a fundamental differentiator. This development is set to disrupt traditional manufacturing software providers and automation companies, pushing them to integrate more sophisticated AI capabilities into their offerings or face obsolescence.

Wider Significance in the AI Landscape

The ascent of AI in manufacturing marks a critical juncture in the broader AI landscape, signaling a maturation of AI from theoretical research to tangible, industrial application. This trend aligns with the increasing emphasis on "edge AI" and "industrial AI," where intelligent systems operate directly on the factory floor, processing data locally and making real-time decisions. The impact extends beyond mere economic efficiency; it touches upon job roles, workforce development, and even environmental sustainability. While concerns about job displacement are valid, initiatives like Georgia AIM highlight a proactive approach to workforce reskilling and upskilling, aiming to create new, higher-skilled jobs in AI development, maintenance, and oversight.

The shift towards AI-driven factories also raises important questions about data privacy, cybersecurity, and ethical AI deployment, particularly as AI agents gain more autonomy in critical production processes. Compared to earlier AI milestones focused on consumer applications or theoretical breakthroughs, the current wave in manufacturing represents a tangible step towards AI's pervasive integration into the physical world, managing complex machinery and intricate supply chains. This evolution underscores AI's potential to address global challenges, from enhancing resource efficiency to fostering more resilient and localized supply chains, thereby contributing to broader societal goals.

Exploring Future Developments

Looking ahead, the trajectory of AI in manufacturing points towards increasingly autonomous and self-healing factories. Near-term developments will likely see the widespread adoption of AI-powered digital twins, creating virtual replicas of physical assets and processes to simulate, optimize, and predict performance with unprecedented accuracy. The integration of advanced generative AI models, akin to Amazon's DeepFleet, will extend beyond robotics coordination to encompass entire production lines, enabling dynamic reconfigurations and adaptive manufacturing processes in response to real-time demand fluctuations or material shortages.

Long-term, experts predict the emergence of truly "lights-out" manufacturing facilities, where AI agents and robots operate with minimal human intervention, handling everything from design optimization to quality control and logistics. Challenges remain, particularly in developing robust, explainable AI systems that can operate reliably in complex industrial environments, ensuring data security across interconnected systems, and addressing the ongoing need for a skilled workforce capable of interacting with these advanced AI systems. The next frontier will involve AI systems that can not only optimize existing processes but also autonomously innovate new manufacturing techniques and product designs, pushing the boundaries of what's possible in production.

A Comprehensive Wrap-Up: The Dawn of Intelligent Production

The integration of AI into manufacturing, exemplified by initiatives like Georgia AIM and Amazon's 'model factory' approach, represents a transformative era for global industry. Key takeaways include the profound impact of AI agents on optimizing everything from predictive maintenance and quality control to production scheduling and energy management. This development signifies AI's maturation into a powerful tool for real-world industrial application, moving beyond basic automation to intelligent, adaptive systems that continuously learn and improve.

The significance of this development in AI history cannot be overstated; it marks a pivotal shift towards intelligent production ecosystems, promising unprecedented levels of efficiency, flexibility, and resilience. As AI continues to evolve, its long-term impact will reshape not only how goods are made but also the global economy, workforce dynamics, and environmental sustainability. What to watch for in the coming weeks and months will be further announcements of successful AI deployments in diverse manufacturing sectors, the emergence of new AI-driven manufacturing solutions from startups, and the continued evolution of workforce development programs designed to prepare for this intelligent industrial future.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms. For more information, visit https://www.tokenring.ai/.