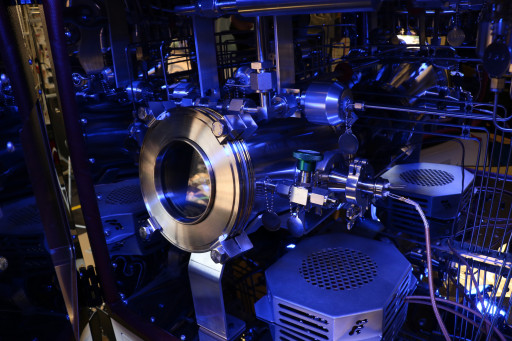

Forge Nano's Pandora ALD Tool

Forge Nano's technology and ALD tools are used to enhance materials and improve product performance.

THORNTON, Colo. - June 23, 2022 - (Newswire.com)

Forge Nano, leaders in atomic layer deposition (ALD) technology and equipment, are working to unlock the next generation of materials science. Through a full product line of ALD equipment addressing large scale manufacturing all the way down to fundamental R&D, Forge Nano has developed nano-coating solutions that are cost-effective, and can improve nearly any product from the atoms up.

"For decades, ALD has been relegated to bench-top exercises and the world of peer-reviewed articles," says James Trevey, Ph.D., CTO of Forge Nano. "It's like we're selling wireless internet in a world of Cat 5 ethernet cables. ALD delivers greater performance for a lower cost than incumbent technology for nearly any application, and now we have brought this technology to the commercial environment at true manufacturing scale."

Atomic Layer Deposition (ALD) is a surface engineering technique whereby an extremely thin coating (as thin as a single layer of atoms) is applied to a wide range of materials, powders, or objects. This process can be repeated to build up multiple layers on nearly any surface, producing robust coatings that can be engineered to enhance or add to the characteristics of the material being coated.

Conventional coating techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) have been the standard techniques used in many industries in the past, but as ALD is now available for any material at commercial scale, their time is limited. Forge Nano's team of scientists and engineers have developed a line of ALD tools that make the technology cost-effective and practical to apply in small-scale lab environments all the way up to full-scale commercial manufacturing settings. Case in point - Forge Nano has already demonstrated commercial success in many markets, including batteries, pharmaceuticals, and semiconductors.

Batteries - Making better, longer lasting, safer batteries

Forge Nano ALD coatings have been demonstrated to improve energy density, lifetime, safety, and cost of batteries. In an electric vehicle these benefits would translate to a lower cost, longer range, faster-than-fuel recharge times, and an EV battery that can last for at least 20 years and is better suited for recycling than current EV batteries. Forge Nano's ALD techniques have also been shown to be more cost effective, more efficient, more precise, and more environmentally friendly than batteries made with other coating techniques.

Pharmaceuticals - Imagine controlled, single-dose, temperature-stable vaccines that can be effectively distributed around the globe without the fear of spoilage.

Forge Nano ALD coatings have been used by pharmaceutical companies to apply various characteristics to medications or vaccines. ALD coatings can make a vaccine thermostable, eliminating the need for refrigeration. Time release properties can be applied as well, allowing multiple doses to be combined into a single treatment or injection. This can make the medication or vaccine easier to distribute to rural areas and eliminates the need for additional doses or boosters.

Semiconductors - Optimizing Next-Gen devices at the atomic scale.

Forge Nano ALD coatings can be applied to semiconductor wafers and components to create hermetic, pin-hole free, low stress thin films that offer excellent uniformity and precision required by semiconductor manufacturers. In addition to producing superior coatings, Forge Nano tools can produce ALD coatings faster and more efficiently than anyone else, making Forge-enabled semiconductors

Thanks to the scalability of Forge Nano's extensive research and development, ALD technology that was once thought of as too expensive is now accessible and practical even at the smallest of scales. Forge Nano is using its manufacturing expertise to provide R&D equipment to universities, national labs, and centers of excellence, establishing ALD as a viable commercial pathway for materials science researchers. This is contrasted by the many companies Forge Nano has worked with to integrate ALD into their manufacturing processes, installing high-volume equipment capable of coating enormous amounts of materials, powders or objects.

For those not ready to make the investment in Forge Nano's ALD equipment, R&D and toll coating services are available as well. Forge Nano offers their world-class ALD technical team to develop coating solutions and run proof of concept tests. Forge Nano is also uniquely equipped to offer toll coating services, where an organization may entrust Forge Nano to produce the ALD coatings with their in-house equipment.

To find out more about Forge Nano's proprietary atomic layer deposition (ALD) processes and equipment, visit ForgeNano.com.

Media: Please direct inquiries to Ron Benfield (ron@acorn-woods.com) at Acorn Woods Communications

About Forge Nano

As pioneers in precision surface engineering, our proprietary Atomic Layer Deposition (ALD) technology is being made available to a wide range of applications, from consumer electronics and lithium-ion batteries to medical devices and raw materials used in manufacturing. The superior coatings produced by our ALD equipment allow us to unlock a material's performance at the atomic level, optimizing characteristics like conductivity, thermostability, and corrosion resistance, to name a few. Our team of scientists have worked with an impressive portfolio of commercial partners to develop custom ALD solutions to meet any need at any scale, from small-scale R&D and laboratory work to large-scale high-volume production lines. For more information, visit www.ForgeNano.com.

Press Release Service by Newswire.com

Original Source: How Forge Nano is Engineering the Future, One Atom at a Time