Austin - January 12, 2026 - Manufacturing companies are increasingly relying on training videos to capture shop floor knowledge, yet many struggle to convert those recordings into usable Standard Operating Procedures (SOPs) that workers can reference during daily operations.

Across assembly lines, maintenance teams, and quality inspections, factories record thousands of hours of process demonstrations each year. However, most of that knowledge remains locked inside long, unsearchable videos. When technicians need a specific step, safety check, or machine setting, they are often forced to scrub through 30–60 minute recordings instead of consulting a clear, structured SOP.

Docsie, a knowledge orchestration platform used by industrial and enterprise organizations, addresses this gap by converting training videos directly into structured, searchable manufacturing SOPs.

“Video is becoming the raw material for SOPs — not the final format,” said Philippe Trounev, CEO of Docsie.“Manufacturing work is physical and visual, so teams naturally record it. The problem is that videos alone don’t scale as operational documentation. SOPs still need to exist, but very few teams have the time or resources to write them manually.”

The Manufacturing SOP Breakdown

Unlike software documentation, manufacturing SOPs must describe physical actions performed in real environments, including:

-

Assembly steps and correct part orientation

-

Machine operation and safety procedures

-

Quality inspection and defect identification

-

Maintenance, calibration, and changeover routines

Traditional SOP creation often takes 8–12 hours per procedure, typically requiring senior technicians or engineers to stop production work in order to document it. As a result, many manufacturers operate with outdated SOPs — or rely entirely on informal knowledge sharing.

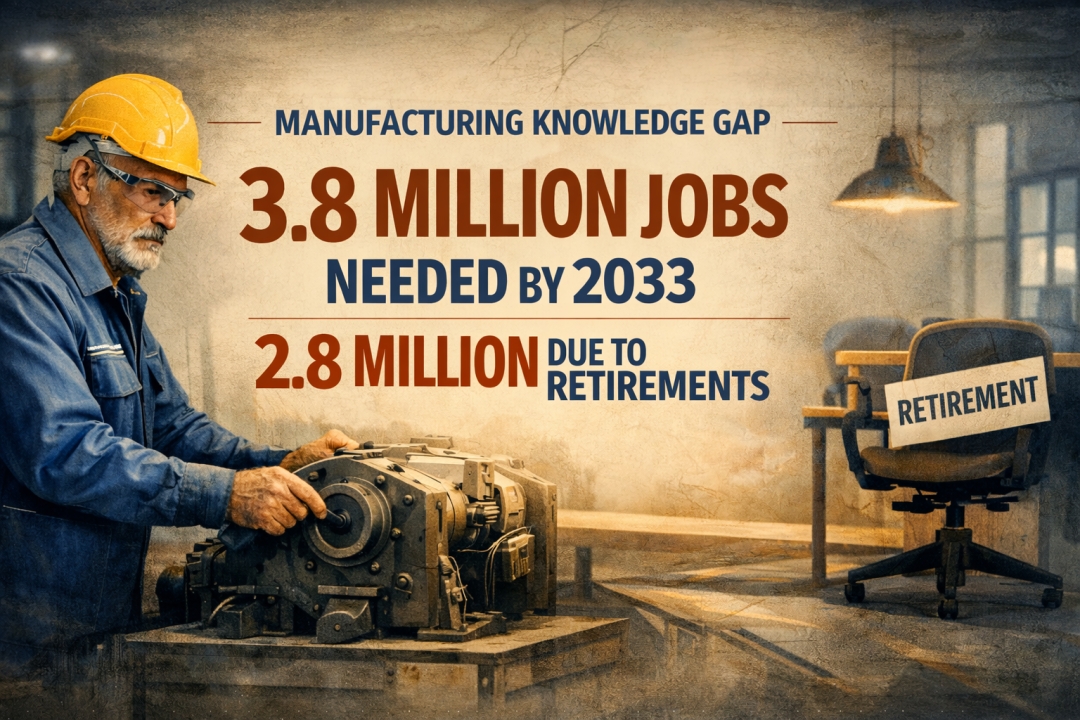

Retirement Is Accelerating the Knowledge Gap

The challenge is intensifying as experienced workers retire.

According to Deloitte and The Manufacturing Institute, the manufacturing sector will need to fill 3.8 million jobs by 2033, with 2.8 million of those roles driven directly by retirements. Much of the departing workforce’s expertise exists only in hands-on demonstrations, informal walkthroughs, or recorded training sessions — not in structured documentation.

“We realized most of our real SOPs existed only in videos and people’s heads,” said a training manager at a multi-site manufacturer.“We were recording procedures constantly, but nobody could actually use those recordings on the shop floor when they needed a quick answer.”

From Training Video to Manufacturing SOP

Docsie’s manufacturing SOP software analyzes existing training videos and automatically generates:

-

Step-by-step SOPs with screenshots extracted from key moments

-

Searchable procedures indexed by machine, process, or part number

-

Safety warnings and compliance notes captured from verbal instructions

-

Multi-language SOPs for global manufacturing teams

Instead of replaying full videos, workers can search directly for the exact step or instruction they need.

“We filmed a maintenance procedure once and Docsie turned it into a structured SOP in minutes,” said a production supervisor at an automotive supplier.“Technicians now search the SOP instead of calling a supervisor or replaying videos.”

Compliance and Audit Readiness

Manufacturers in regulated industries — including food production, pharmaceuticals, aerospace, and medical devices — must maintain current, accessible SOPs for audits and inspections.

“Regulators don’t accept ‘it’s in a video somewhere,’” Trounev added. “They expect controlled, versioned SOPs. Video-to-SOP automation makes compliance documentation achievable without slowing down operations.”

Why Video-First SOP Creation Is Gaining Adoption

Manufacturing teams increasingly capture knowledge on video because it:

-

Reflects real working conditions

-

Requires minimal disruption to production

-

Preserves expert knowledge before retirement

What has been missing is a scalable way to convert those recordings into operational documentation. Video-to-SOP automation closes that gap.

Availability

Docsie’s manufacturing SOP software supports standard video formats, mobile recordings, and integrates with ERP systems, quality management platforms, and learning management systems.

Media Contact

Company Name: Docsie Inc.

Contact Person: Philippe Trounev

Email: Send Email

Phone: 4169028771

Address:140 Yonge Street Suite 200

City: Toronto

State: ON

Country: Canada

Website: https://www.docsie.io