In the fast-evolving world of metal fabrication, achieving flawless finishes and maintaining production efficiency are no longer optional—they are essential. Among the tools leading this transformation is the metal sanding machine, a cornerstone in the pursuit of precision, durability, and surface perfection. At SAMACH Machinery, innovation meets craftsmanship, offering a comprehensive range of metal sanding solutions designed for modern industries seeking superior surface quality and operational efficiency.

The Rising Demand for Metal Sanding Machines

From automotive manufacturing and aerospace engineering to stainless steel furniture production, metal sanding machines have become indispensable. Traditional manual sanding methods, once the norm, no longer meet today’s demands for consistency, speed, and precision. As manufacturers strive for uniform finishes, reduced labor costs, and environmentally responsible operations, automated metal sanding equipment has become the preferred choice.

The growing emphasis on product aesthetics and performance means that even the smallest imperfections in a metal surface can compromise a brand’s reputation. SAMACH’s sanding machines solve this by ensuring precise, repeatable results through advanced automation, optimized pressure control, and uniform abrasive application—making them essential tools for any metalworking facility focused on excellence.

Precision Engineering: The Core of SAMACH’s Innovation

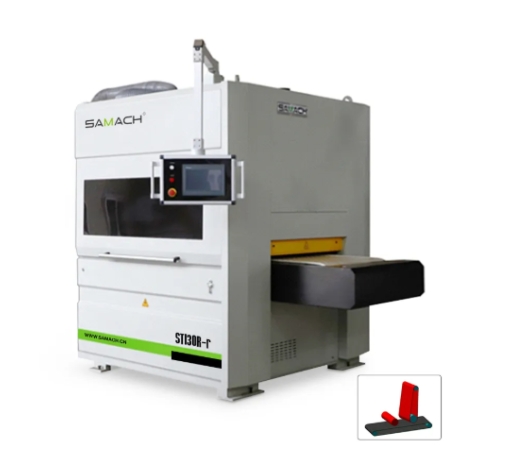

Each SAMACH metal sanding machine is engineered with precision mechanics and digital intelligence to handle a wide range of materials—from carbon steel and aluminum to stainless steel and brass. High-speed abrasive belts, adjustable feeding systems, and digital control panels give operators complete command over every detail of the sanding process.

One of SAMACH’s key innovations lies in its multi-stage sanding system, which allows rough, intermediate, and fine polishing in a single pass. This not only improves production speed but also ensures consistency across large volumes of workpieces. Whether for flat sheet metal or complex contours, SAMACH machines deliver uniform grain direction, burr removal, and surface smoothness—ready for coating, painting, or welding.

Sustainability Meets Efficiency

In addition to performance, SAMACH emphasizes sustainability and energy efficiency. Its metal sanding machines are equipped with dust extraction systems, ensuring cleaner air in the workplace and compliance with environmental regulations. By optimizing abrasive material consumption and reducing rework, these machines help manufacturers minimize waste and maximize profits.

Energy-efficient motors and variable speed drives further enhance performance, allowing users to fine-tune operations according to different materials and finish requirements while saving power—a key advantage in today’s eco-conscious manufacturing environment.

Wide Applications Across Industries

SAMACH’s metal sanding machines are designed for versatility. They are widely used in industries such as:

- Automotive and Aerospace: Achieving precision surface finishes for structural components and panels.

- Stainless Steel Fabrication: Polishing kitchen equipment, elevators, and decorative panels.

- Machinery and Tooling: Removing burrs and oxide layers for improved component durability.

- Architectural Metalwork: Ensuring high-quality visual finishes on railings, signage, and fixtures.

Each application benefits from SAMACH’s engineering excellence—providing stable, consistent, and repeatable results, even under demanding production conditions.

The Digital Edge: Smart Control for Smarter Manufacturing

SAMACH integrates intelligent control systems into its sanding machines, allowing operators to set pressure, speed, and sanding depth through an intuitive touchscreen interface. With built-in fault diagnostics and automatic adjustment features, downtime is significantly reduced, ensuring continuous productivity.

As Industry 4.0 becomes the standard, SAMACH’s digital-ready machines can be integrated into smart factory systems, enabling real-time performance monitoring and data-driven decision-making. This not only streamlines operations but also aligns with the global shift toward automation and intelligent manufacturing.

Why Choose SAMACH

What distinguishes SAMACH from others in the industry is its dedication to quality, reliability, and innovation. Each machine is manufactured using premium components, tested under strict conditions, and backed by professional technical support. The result is equipment that delivers long-lasting performance, minimal maintenance, and exceptional return on investment.

Moreover, SAMACH offers customized solutions tailored to specific production needs. Whether it’s adjusting belt width, adding polishing modules, or integrating with conveyor systems, the company provides complete flexibility to help clients optimize their workflow.

Looking Ahead: The Future of Metal Surface Finishing

As global industries continue to demand higher standards of precision, speed, and sustainability, metal sanding machines will play an increasingly pivotal role. SAMACH’s continued investment in research and development ensures it remains at the forefront of this evolution—offering products that not only meet current needs but also anticipate future challenges.

Manufacturers who embrace modern sanding technologies today position themselves for success in tomorrow’s competitive landscape. SAMACH stands ready to support this transformation, empowering industries worldwide to achieve perfect surfaces with greater efficiency and lower environmental impact.

To learn more about SAMACH’s complete range of metal sanding machines, visit https://www.samach.cn/collections/metal-sanding-machine.

Media Contact

Company Name: Qingdao Samac International Trading Co., Ltd.

Contact Person: Media Relations

Email: Send Email

Phone: +86-532-85063301

Address:Excellence Century Center

City: Qingdao

State: Shandong

Country: China

Website: https://www.samach.cn/