HDPE Telecom pipe, or PLB HDPE Telecom Ducts, Telecommunication ducts, Optical fiber duct / Microduct, outdoor telecommunication optical fiber, optical fiber cable, and Large diameter pipe, etc…, is a new type of composite pipe with a silicone gel solid lubricant on the inner wall. The main feature of this type of pipe is the silicon core layer on the inner wall, which is a solid, permanent lubricant, extruded and moulded synchronously with the wall of the high-density polyethylene (HDPE) pipe, uniformly distributed throughout the inner wall of the pipe, which will not peel off or detach, and ensures the service life of the pipe.

HDPE Silicon Core Tube is widely used in optical cable communication network systems for highways and railways because of its low coefficient of friction, good sealing performance, chemical corrosion resistance, and low engineering cost. In addition, it is also suitable for construction, piping and water supply and drainage, HVAC and other industries.

What are the advantages of HDPE Telecom pipe?

Low coefficient of friction: The inner silicon core layer provides an extremely low coefficient of friction, which facilitates the repeated extraction of cables inside the pipe.

Durability: The silicon core layer has the same physical and mechanical properties as HDPE, ensuring the strength and durability of the pipe.

Corrosion resistance: Wide range of suitable temperature, corrosion resistance, applicable to a variety of environments.

Flexibility: good flexibility enables it to adapt to various terrains and slopes. Convenient construction: convenient and quick construction, low project cost.

In the processing and granulation of HDPE silicon core pipe raw materials, the following common problems may be encountered:

Poor extrusion: If the temperature setting of the extruder is too low, it may result in poor extrusion, which in turn may affect the surface smoothness of the product.

Surface bubbles and skid marks: Raw materials that are too wet may create air bubbles during extrusion, and these bubbles may form uniform scars or skid marks as they pass through the shaping changeover sleeve.

Excessive coefficient of friction of the inner wall of the HDPE Telecom pipe: The coefficient of friction of the inner wall of the silicone core tube is too high, which affects the speed of cable unwinding, and the repeated extraction of the cable inside the tube is hindered, thus affecting the production efficiency.

Problems with cross-section quality: The cross-section of the silicone core pipe may have bubbles, cracks or inconsistencies in thickness, all of which can affect the overall quality and performance of the pipe.

SILIKE Silicone masterbatch – an effective solution to improve the processability and quality of HDPE Telecom pipe

In order to solve these problems, it is necessary to strictly control the quality of raw materials, ensure the precise control of the extrusion process, as well as regular quality testing in the production process. Many merchants in order to reduce the friction coefficient of the inner wall of the silicon core pipe, to improve the cable in the pipeline release speed, in general, will be in the HDPE silicon core pipe material granulation add silicone masterbatch, the following is the main reason for adding silicone masterbatch:

Improvement of processability: SILIKE Silicone masterbatch LYSI-404 can improve plastic processing fluidity and release performance, reduce torque, reduce equipment wear.

Enhance product quality: adding SILIKE Silicone masterbatch LYSI-404 can improve the smoothness, finish, scratch resistance, abrasion resistance and other surface properties of the products.

Reduce the coefficient of friction: adding SILIKE Silicone masterbatch LYSI-404 in the granulation process of HDPE silicone core pipe raw materials can significantly reduce the coefficient of friction of the inner wall of the silicone core pipe and improve the smooth surface, thus greatly improving the speed of unwinding, and the repeated extraction of cables and wires inside the pipe will not be hindered and the service life of the products will be prolonged.

In summary, HDPE silicone core pipe has a wide range of applications in many fields due to its unique properties, and the addition of silicone masterbatch further enhances its processing and use performance.

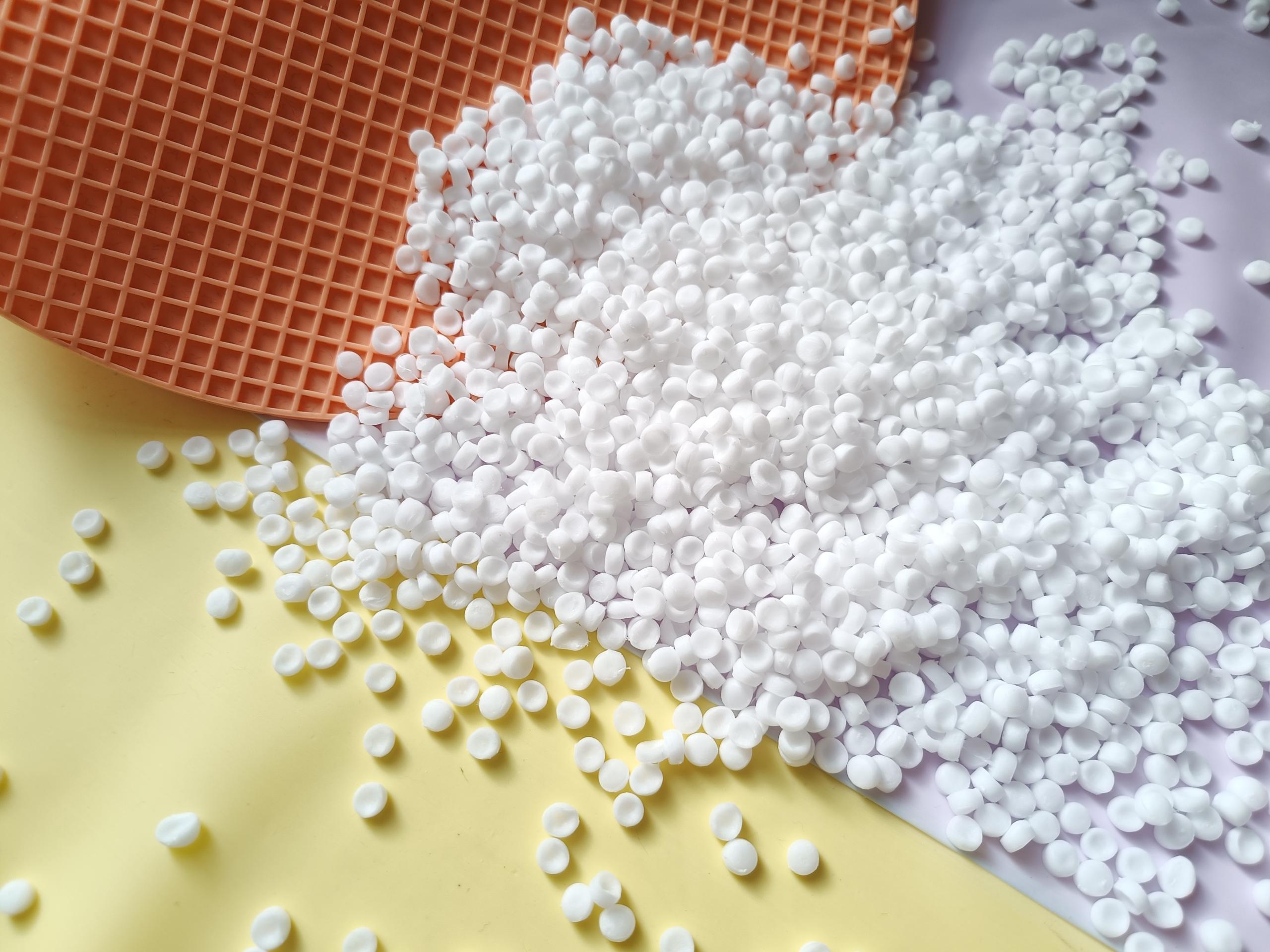

SILIKE Silicone masterbatch LYSI-404 is a pelletized formulation with 50% ultra high molecular weight siloxane polymer dispersed in High-density polyethylene (HDPE). It is widely used as an efficient additive for PE compatible resin system to improve the processing properties and surface quality, such as better resin flow ability, mold filling & release, less extruder torque, lower coefficient of friction, greater mar and abrasion resistance.

If you want to know more about SILIKE Silicone Masterbatch, you can do so by browsing our website: www.siliketech.com.

Contact us at Tel: +86-28-83625089 or +86-15108280799, or reach out via email: amy.wang@silike.cn

Media Contact

Company Name: Chengdu Silike Technology Co.,Ltd.

Email: Send Email

Country: China

Website: https://www.siliketech.com/