Sheet metal bending method

Sheet metal bending methods are based on a relatively simple technique that entails applying force on a flat metal sheet to change its shape. Virtually every manufacturing industry uses bending techniques for their cost-effectiveness, versatility, and simplicity.

The types of sheet metal bending processes include U-bending, V-bending, roll bending, rotary bending, and wipe bending. Each has its benefits and limitations, which manufacturers consider for sheet metal fabrication parts.

This article delves into the different sheet metal bending techniques to help in determining the most suitable for a project. It also touches on selection tips and the main applications.

What is Sheet Metal Bending?

Sheet metal bending is the measured application of force on flat metal sheets to convert them into durable and strong shapes. The resulting components can be used for either aesthetic or functional purposes.

The sheet metal bending process is done on metals like aluminum, carbon steel, copper, and stainless steel. These metals are preferable mostly for their flexibility. Then, there are specific properties depending on the project.

For instance, aluminum is light, carbon steel offers strength, and copper is very corrosion-resistant. Therefore, understanding how to bend aluminium sheet is critical for any sheet metal fabrication service provider, as it is for the other metals.

History of Sheet Metal Bending

Industrial-scale sheet metal bending started during the Industrial Revolution, towards the end of the 19th century. The concept was largely enhanced by the emergence of technologies such as press brakes and manufacturing assembly lines.

Air bending came a little later in the century than coining and bottoming bending methods, which emerged in the 1970s.

General Steps for Bending Sheet Metal

There are various machines for bending sheet metal, but the most popular one is the press brake. The bending principle or approach is similar regardless of the machine.

Here are the main steps for any sheet metal bending method:

- Identify the Design Parameters

Designers often refer to sheet metal bend radius charts for bend specifications, such as sheet metal bend allowance.

- Set Up the Bending Machine

Using the right machine, punches, and dies is as important as the design step.

- Align the Sheet Metal

The sheet metal should be positioned accurately, with bend lines aligned with the tool.

- Bend the Sheet Metal:

The bending force should be applied gradually, and the process closely monitored.

Different Sheet Metal Bending Methods

There are many methods to bend sheet metal, some modern and some more conventional. The most common ones are U-bending, roll-bending, V-bending, edge-bending, wipe-bending, and rotary bending.

Below is further discussion about the different sheet metal bending methods.

V-bending

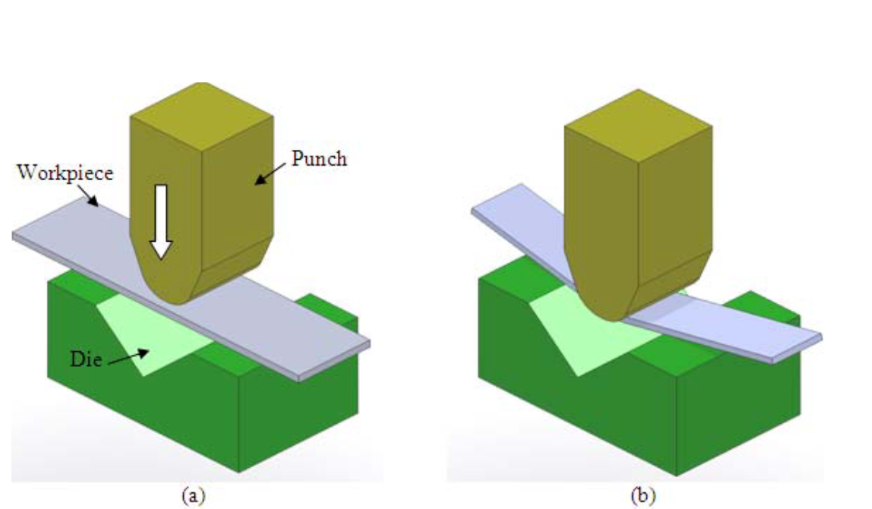

V-bending uses a punch and a V-shaped die to give the sheet metal a V shape. Both the punch and groove are V-shaped. The bends on the metal can be of any angle, depending on the shape of the die and punch. V-bending is the most common sheet metal bending method.

V-bending process

U-Bending

The mechanism of U-bending is similar to that of V-bending. The difference is that instead of a V-shaped die and punch, U-shaped ones are used. So, the sheet will be U-shaped.

Air bending

Air bending entails pressing a sheet of metal using a punch and die. This method is unique and different from U-bending and V-bending because the material is not clamped.

Roll-Bending

Roll-bending is so called because it shapes the sheet metal into curves, rolls, or tubes. The main features of roll-bending are the rollers.

Roll bending

The number and size of the rolls can be set according to the sheet metal fabrication requirements.

Providers of metal cutting and bending services use the roll metal bending process to make shelves, panels, and tracks for various applications.

Rotary Bending

Rotary bending entails clamping the sheet metal to a die, which, when rotated, draws the sheet metal around it to produce the desired shape.

An internal mandrel is part of this setup to prevent potential wrinkling of the sheet metal. The advantages of rotary bending include safeguarding the sheet’s surface quality and the capability to produce obtuse angles.

Wipe-Bending

This method involves placing the sheet metal between a wipe die and a pressure pad. A punch is then used to bend the protruding edge of the sheet metal. The technique has a good mechanical advantage that helps bend the sheet metal with minimal force.

Common Tools Used in Sheet Metal Bending

The most common sheet metal bending tools and equipment include roll bending machines, press brakes, and folding machines. Choosing the right one for a project is crucial.

Roll-bending Machine

A roll-bending machine is made up of three rollers, between which the sheet metal is passed and bent. This equipment is perfect for producing cylindrical components from sheet metal.

Press Brake

The basic parts of a press brake are a punch and a die. The punch forces the sheet against the die. This powerful machine can make simple and complicated bends alike.

Folding Machine

Then there is the folding machine, which clamps sheet metal and uses a moving beam to fold it.

Applications of Sheet Metal Bending

Sheet metal bending is a common process used in various industries served by ProleanTech, including automotive, aerospace, electronics, HVAC, and structural.

Some of the common applications in these industries are listed below;

Sheet metal bending applications in the automotive industry

- Exhaust system parts

- Engine brackets

- Body panels

Sheet metal bending applications in the aerospace industry

- Fuselage panels

- Airframe parts

- Landing gear components

- Wing supports

Sheet metal bending applications in the electronics industry

- Battery covers

- Housings

- Mounting brackets

Sheet metal bending applications in HVAC

- Ductwork

- Mounting brackets

- Heat exchanger casings

Sheet metal bending applications in structures

- Window and door frames

- Steel reinforcements

- Roof flashing

- HVAC ducts

Tips for Choosing a Sheet Metal Bending Method

Sheet metal fabrication professionals have a wide array of sheet metal bending methods to choose from. Several factors should be considered when choosing a bending method to optimize results, and they include;

- Type of metal

- Metal sheet thickness

- Production volume

- Cost of the technology

- Operator’s skill level

The combination of factors emphasized can vary depending on the details of a project.

Conclusion

The importance of sheet metal bending is evident from the variety of methods available. Industries like electronics and automotive use the process and its various techniques to produce all manner of components.

A good selection of a sheet metal bending method can mean the difference between rejected parts and high-quality ones. Sheet metal bending technologies are widely recognized in China and overseas.

The sheet metal bending services at the company provide endless possibilities for high-quality parts that enhance manufacturing goals.